Rolled Collars - Vibration Isolator and Vibration Absorber

Nyltite Rolled Collars fit under the heads of screws nuts, rivets or the like. Their design provides a lock-and-seal mechanism (see below) that makes them far superior to any conventional washer. Their design enables them to act in concert with screws and bolts as sealing and locking fasteners, and depending on the application, vibration insulators. They cause the screw to lock in place and at the same time create a seal that is incredibly resistant to harsh temperature and chemical environments.

Nyltite Rolled Collars fit under the heads of screws nuts, rivets or the like. Their design provides a lock-and-seal mechanism (see below) that makes them far superior to any conventional washer. Their design enables them to act in concert with screws and bolts as sealing and locking fasteners, and depending on the application, vibration insulators. They cause the screw to lock in place and at the same time create a seal that is incredibly resistant to harsh temperature and chemical environments.

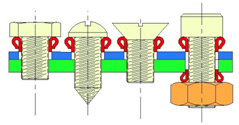

The collar is a section of extruded tubular nylon rolled backward upon itself as shown in the illustration. The benefit of this design is a controlled flow during the tightening process providing unique characteristics that washers typically do not. These characteristics include Lock-and-Seal, electrical insulation, mechanical isolation, thermal isolation and vibration resistance.

How It Works as a Faster / Sealer

When a fastener equipped with a Nyltite rolled collar is tightened, the collar compresses and the nylon is forced to flow inwards, away from the structurally strong outer rim, contrary to the conventional compressible washer that flows away from the fastener. This is the mechanism of Controlled Flow. As a result of this inward flow, the screw head, the shank and the work piece become filled with the highly compressible plastic material of the Nyltite Rolled Collar forming an excellent screw / bolt lock, screw / bolt seal, insulator and isolator.

Versatility and Customization

Because the Nyltite rolled collar inherently exhibits several advantageous characteristics listed above, we can design it so that any one characteristic or combination of characteristics are enhanced to fit your application. For example, we can design it to be an excellent electrical insulator, thermal insulator and/or isolator, depending on your requirements. Mechanical and electrical isolation from the work piece can eliminate galvanic corrosion. We can also design it to eliminate chipping and crazing of the surface of the screw threads and work piece.

The natural lubricity of the assembled Nyltite nylon rolled collar reduces friction during the tightening process, requiring less torque to get full screw tension than do assemblies without a Nyltite nylon rolled collar. This characteristic provides a lock and/or sealing assembly which we can enhance to fit your application.

Ability to Withstand Harsh Environments – Nyltite Rolled Collars maintain the integrity of the lock and seal, insulation and isolation through the harshest of environments. These collars resist attack by salt water, hot oils, refrigerants, alkalis, diluted mineral acids and most solvents and chemicals. The working temperature range for this product is –70° F to +250° F.

Relationship to other Nyltite Products

When fitted with a shank extension, the Nyltite Rolled Collar becomes a Nyltite Headed Sleeve. The Nyltite Headed Sleeve has all the fastening and sealing properties as does the Rolled Collar and in addition, provides other functions as described in the Nyltite Headed Sleeve section.

When fitted with a shank extension, the Nyltite Rolled Collar becomes a Nyltite Headed Sleeve. The Nyltite Headed Sleeve has all the fastening and sealing properties as does the Rolled Collar and in addition, provides other functions as described in the Nyltite Headed Sleeve section.

|

|

| PART | SCREW | NOMINAL | ID | W | OD | CD | TH | CH |

| NUMBER | SIZE | metric | +.102/-.076 | +/-.051 | +/-.203 | +.635/-.381 | +/-.762 | (REF) |

| NRC-02.5M | M2.5 | 2.5 | 2.57 | 0.30 | 3.10 | 4.42 | 2.03 | 1.63 |

| 10079 | M3 | 3 | 3.07 | 0.33 | 3.66 | 5.03 | 2.03 | 1.63 |

| 10081 | M4 | 4 | 4.06 | 0.38 | 4.75 | 6.22 | 2.74 | 2.08 |

| 11752 | M5 | 5 | 5.05 | 0.43 | 5.84 | 7.87 | 2.92 | 2.34 |

| 10097 | M6 | 6 | 6.10 | .043 | 6.86 | 8.99 | 3.10 | 2.59 |

| 11750 | M8 | 8 | 8.08 | 0.51 | 9.02 | 11.99 | 3.35 | 2.67 |

| 11751 | M10 | 10 | 10.06 | 0.51 | 11.00 | 12.93 | 3.96 | 3.15 |

| 10235 | M12 | 12 | 12.09 | 0.56 | 13.13 | 15.62 | 4.45 | 3.56 |

| NRC14M | M14 | 14 | 14.07 | 0.56 | 15.11 | 17.78 | 4.88 | 3.94 |

| 11652 | M16 | 16 | 16.05 | 0.64 | 17.25 | 20.32 | 5.33 | 4.06 |